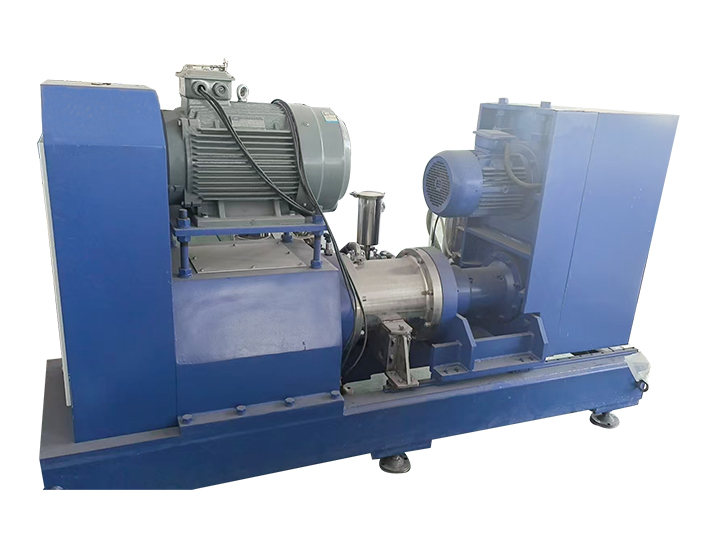

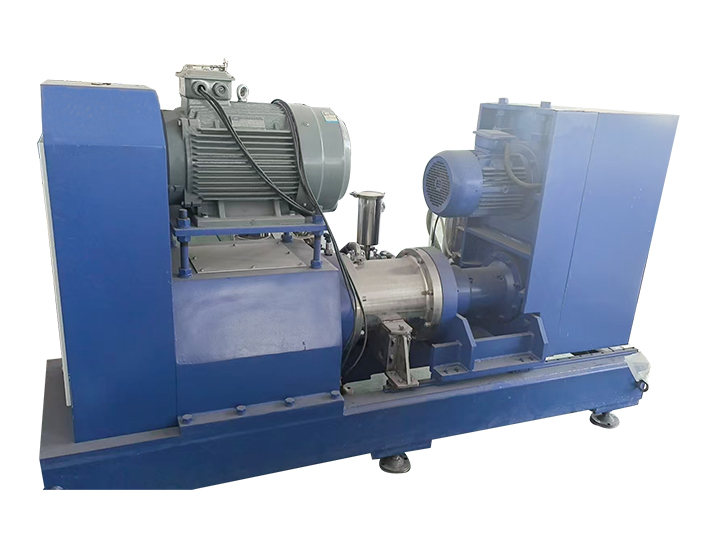

Disc Sand Mill: An Industrial Solution for Efficient Ultra-fine Grinding and Dispersion

Release time:2025-12-09 Visits:322

The disc sand mill is a crucial wet ultra-fine grinding equipment in fine chemicals and industrial manufacturing. It achieves efficient grinding and dispersion of liquid-solid mixed materials through mechanical force, ensuring the final product meets specified fineness indicators. Its core advantages lie in high efficiency, precise temperature control, and wide material adaptability, making it a key equipment in the production processes of many industries.

The working principle of the

disc sand mill is based on mechanical grinding and dynamic separation. Preprocessed raw materials enter the grinding chamber via a delivery pump. The main shaft drives the dispersion disc or turbine to rotate at high speed, agitating the grinding media (such as zirconia beads or glass beads). These media generate intense swirling flow and movement, exerting shear, impact, and friction on material particles to achieve ultra-fine grinding. After grinding, the materials and media are separated by a dynamic separator (such as a rotor gap device), the finished product flows out, and the media remain in the chamber for recycling. The entire process monitors pressure and temperature through electric contact instruments to ensure automatic control and operational safety.

The main characteristics of this equipment include high-efficiency grinding capability. The narrow grinding chamber and high energy density design ensure rapid and uniform particle size distribution, suitable for processing large batches of medium to high viscosity materials. The conical chamber design enhances the back-and-forth movement of grinding beads, improving grinding efficiency and consistency. It has excellent temperature control performance, adopting multiple cooling points such as stator, rotor, and front end plate to expand the cooling area, effectively managing temperature, which is crucial for sensitive materials (such as certain chemicals or pigments). In addition, the equipment uses high wear-resistant materials to manufacture contact parts, prolonging service life, and can be optionally equipped with a PLC automatic control system to monitor and adjust process parameters in real-time, achieving fully automated operation.

Disc sand mills have a wide range of applications covering multiple industrial sectors. In the coating industry, it is used to produce automotive coatings, industrial coatings, and metallic coatings, ensuring color uniformity and fineness compliance. In ink manufacturing, it is suitable for the dispersion treatment of UV inks, electronic inks, and screen printing inks. It is also used for ultra-fine grinding of pigments, dyes, color pastes, as well as electronic chemicals and other fine chemical products. This versatility makes it an indispensable equipment in continuous production environments, supporting high output and high-quality standards.

In conclusion, with its efficient grinding performance, stable temperature control system, and wide applicability, the disc sand mill provides a reliable solution for industrial users. Whether processing water-based or solvent-based materials, it can ensure product fineness and uniformity, helping to improve production efficiency and product quality.