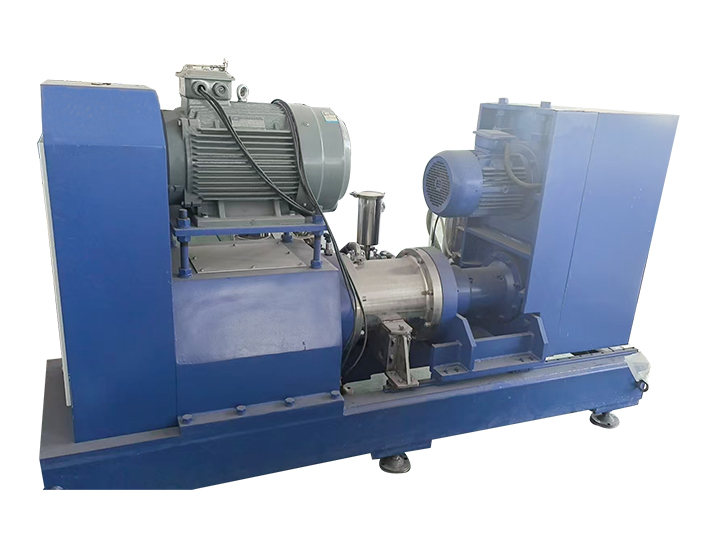

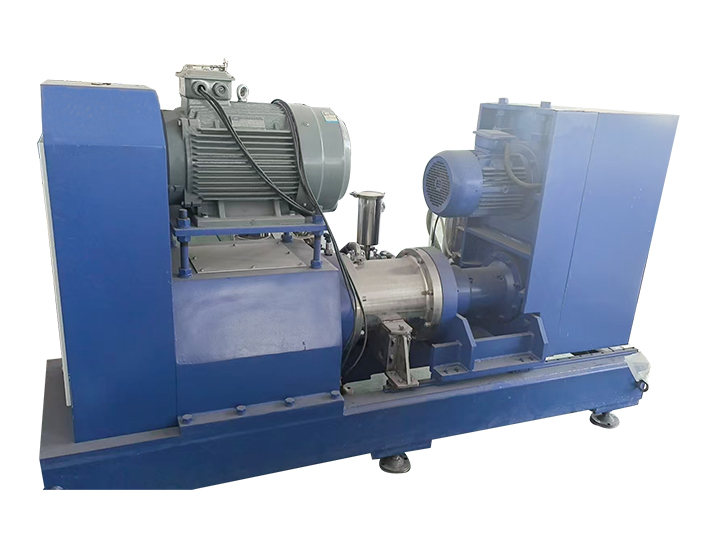

Turbo Sand Mill: Working Principle and Industrial Applications of High-Efficiency Grinding Equipment

Release time:2025-12-09 Visits:341

The turbo sand mill is an efficient grinding equipment with an innovative turbo structure, designed to enhance the performance of traditional sand mills in terms of efficiency, energy consumption, and grinding quality. Its core lies in the design of the turbo component, which generates strong shearing, impact, and frictional forces through high-speed rotation, enabling material particles to reach micron or nanometer-level fineness. Turbo sand mills are widely used in industries such as new energy battery materials, high-end coatings, inks, nanometer new materials, pharmaceuticals, and ceramics, becoming the preferred solution for high-precision grinding applications.

The working principle of the turbo sand mill is based on a motor driving the main shaft to rotate at high speed, driving multiple turbo components to rotate synchronously. After the material enters the grinding cylinder from the feed port, it is mixed with pre-filled grinding media (such as zirconia beads). The rotation of the turbo generates high-intensity shearing, impact, and frictional forces, causing the material particles to be repeatedly ground between the turbo blades and the media. The ground material is discharged through the discharge component, and the entire process is usually accompanied by a cooling system to control the grinding heat and ensure stable product quality.

In terms of core structure, the turbo components of the turbo sand mill are circumferentially fixed on the main shaft and maintain a fixed spacing through spacer sleeves to ensure the stability and efficiency of the grinding area. The turbo blades are designed with specially shaped openings (such as isosceles trapezoids) to optimize fluid dynamics and enhance the collision and shearing effects between materials and media. The equipment also includes parts such as a cylinder, main shaft, sealing system, base, and drive device, with a compact structure designed to reduce energy loss and extend the service life of key components.

The performance advantages are significant. Compared with traditional pin or disc sand mills, the turbo sand mill has higher grinding efficiency and better energy consumption performance. The turbo structure can generate stronger eddy currents and more uniform energy distribution, thereby shortening grinding time, reducing energy consumption per unit product, and helping to control grinding temperature to avoid material denaturation due to overheating. These characteristics make it particularly suitable for fields with extremely high requirements for product fineness and dispersibility.

In industrial applications, turbo

sand mills are widely used in fields such as electronic ceramics, magnetic materials, cosmetics, and pharmaceuticals. Its fully enclosed design ensures no pollution, low maintenance rate, and easy cleaning. The equipment can be optionally equipped with variable frequency speed regulation and PLC control systems, featuring high performance, stable operation, and long service life. The large-area screen separation system supports large-volume continuous production, and the high-precision double-end mechanical seal ensures reliable sealing without leakage. In addition, the turbo sand mill can also choose materials such as ceramics, polymers, and alloy steel according to specific needs to meet the special requirements of different industries.

In conclusion, through its unique turbo design, the turbo sand mill effectively solves the bottlenecks of traditional equipment in efficiency, temperature control, and grinding quality, becoming an ideal choice for high-precision grinding applications. Its efficient, energy-saving, and stable performance enables it to play an important role in multiple industries and promote the continuous progress of grinding technology.