© 2025 Wuxi Xinyang Equipment Technology Co., Ltd. All Rights Reserved.Web Design by Wangke

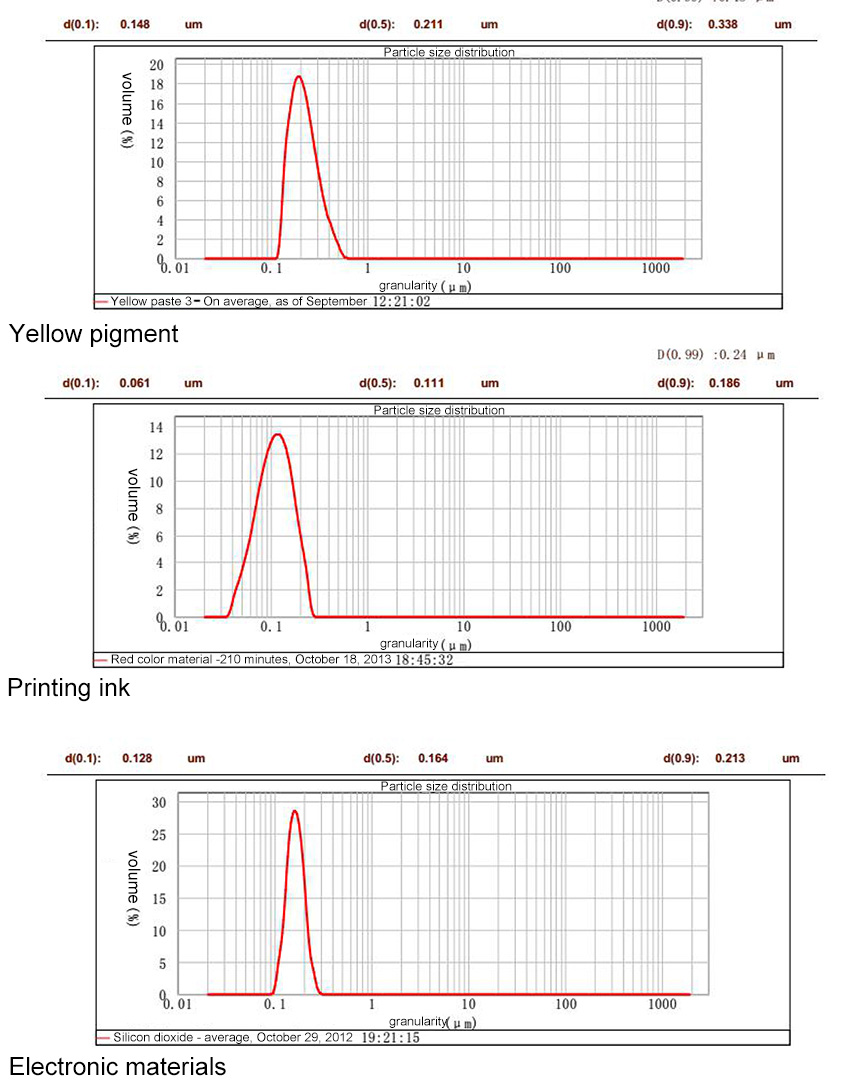

Nano grinding mills operate on the principle of high-energy impact and shear forces. The grinding media, typically beads, are accelerated by a rotor within the mill. As these beads collide with the material, they break it down into finer particles. This process is enhanced by the mill's design, which ensures optimal energy transfer and efficient grinding.

| Structural style | Stick pin self circulating nano grinder |

| Type | R&D type |

| Production capacity | 0.2-2 kg/h |

| Applicable materials | Grinding of liquid slurry |

| External dimensions | 580*500*580 mm |

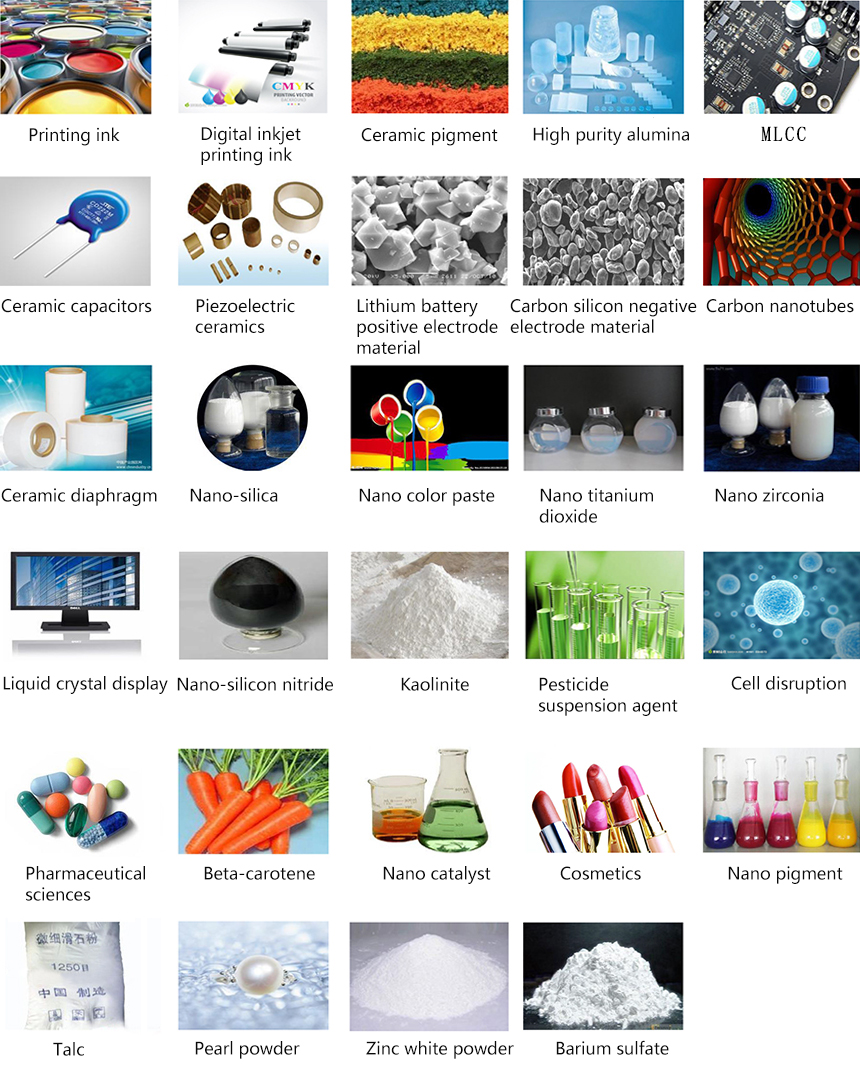

| Application area | Experimental testing, formulation development, and scientific research of various nanomaterials |

| Weight | 45kg |

| Main motor power | 0.75 kW (Taiwanese brand) |

| Touch screen brand | Kunlun Tongtai (brand can be customized according to customer requirements) |

| Model | NM0.3L |

| Feeding capacity | 50-200 g/min |

Tel

QR code

QR code

Top