Comprehensive Analysis of Crushers: Working Principles, Type Selection, and Safe Operation Guide

Release time:2026-01-19 Visits:353

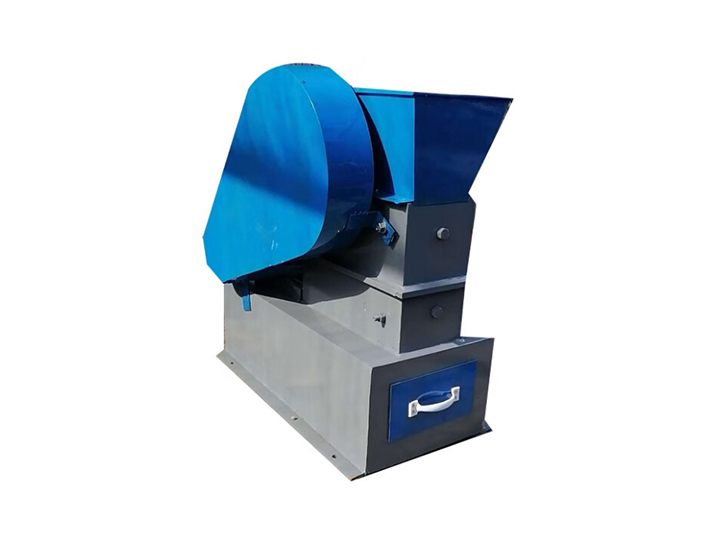

A crusher is a key equipment that uses mechanical force to break large solid materials into particles of desired size, widely used in industrial production, resource recycling, and daily processing. Its core principle is to destroy the internal bonding force of materials by applying external forces (such as impact, shear, extrusion, or grinding) to reduce particle size. The following explanation covers three aspects: working principles, type selection, and safe operation.

I. Working Principles

Crushers achieve material through mechanical energy conversion, with main methods including:

1. Impact crushing: High-speed rotating hammers or blades strike materials, suitable for brittle and hard materials.

2. Shear crushing: Using relatively moving blades to cut fibrous materials (e.g., paper, plastic).

3. Compression crushing: Applying pressure through two working surfaces to crush hard materials (e.g., ores).

4. Grinding crushing: Materials are frictionally peeled between grinding media into fine powder, suitable for ultra-fine powder preparation.

Equipment usually combines multiple methods and controls the discharge through screens, ensuring only particles of are discharged.

II. Types and Selection Guide

According to material characteristics and requirements, common crusher types include:

- Jaw crusher: Used for coarse crushing in mines, with large processing capacity and simple structure.

- Hammer/counterattack crusher: Suitable for medium and fine crushing, such as limestone or construction waste.

- Knife crusher: Specialized for waste treatment (e.g., plastic, wood) and resource recycling.

- Ball mill: Used for ultra-fine grinding in mining and chemical industries.

- Household kitchen waste crusher: Installed under kitchen sinks to handle food waste.

Selection requires comprehensive consideration of:

1. Material properties: Hardness, viscosity, moisture content, and presence of metal impurities.

2. Particle size requirements: Determine the number of crushing stages based on feed size and finished product.

3. Capacity demand: Hourly processing capacity determines the equipment model.

4. Scene adaptation: Fixed type for mines and factories; mobile type for transfer operations such as construction waste.

III. Safe Operation Specifications

When operating heavy

crushers, strictly follow:

1. Protection preparation: Wear safety helmet, goggles, and tight work clothes; avoid long hair or clothing being.

2. Pre-start inspection: Confirm parts are fastened, no foreign objects in the cavity, and lubricate key parts.

3. Standard feeding: Prohibit putting in metals or hard objects to prevent damage to and equipment.

4. Operation taboos: It is strictly forbidden to open the protective cover or reach into the equipment while it is running.

5. Emergency measures: Familiarize with the location of the emergency stop button and immediately cut off power in case of abnormalities.

6. Regular maintenance: Replace worn parts (e.g., hammers, screens) to keep the equipment in good condition.

In conclusion, the efficient use of crushers depends on correct type selection and safe operation. In practical applications, schemes need to be refined based on material characteristics and production requirements to ensure equipment life and operation safety.