Comprehensive Analysis of Ceramic Sand Mills: Core Equipment for High-Efficiency Grinding and Pollution-Free Production

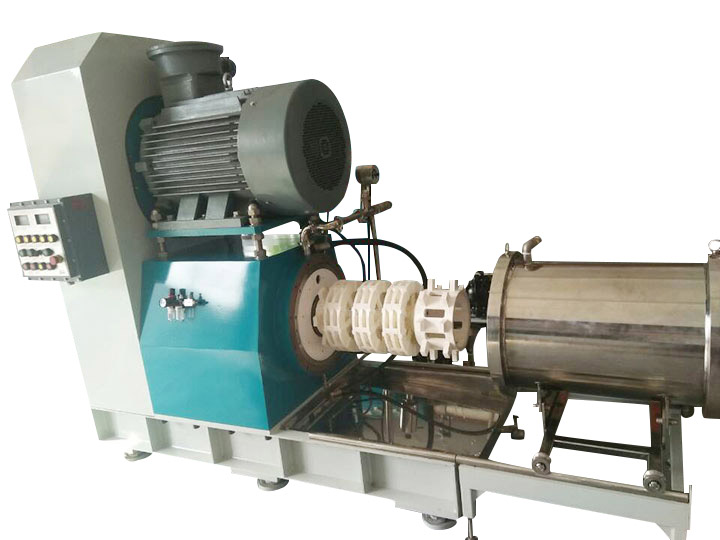

Ceramic sand mills are core equipment in modern fine grinding processes, widely used in multiple industrial fields. It mainly includes two aspects: one is a sand mill with ceramic materials as the core grinding medium, and the other is a sand mill whose parts in contact with materials are made of ceramic materials. The following is a detailed analysis from multiple perspectives.

Ceramic grinding media is the key to achieving efficient grinding in sand mills. Ceramic beads, especially yttrium-stabilized zirconia beads, have excellent properties such as high density, high hardness, high toughness, and chemical inertness. High density provides greater kinetic energy, resulting in high grinding efficiency, especially suitable for processing high-viscosity and hard materials; high hardness and low wear rate ensure that the product is not contaminated and has a long service life; high toughness enables ceramic beads to withstand severe impact and shear inside; chemical inertness ensures that it is suitable for most chemical systems and will not react with materials, thus ensuring product purity.

Compared with other grinding media, glass beads have low density, low hardness and are fragile, suitable only for low-requirement and low-viscosity grinding; steel beads have high density but are prone to rust, and high wear will introduce metal ion contamination, which is not suitable for industries with high purity requirements; alumina beads have high hardness but poor toughness and certain wear. Therefore, sand mills using zirconia ceramic beads have significant advantages in efficiency and purity.

In fields with extremely high requirements for product purity, the parts of the sand mill in contact with materials will be made of ceramic materials to avoid metal ion contamination. This type of design is suitable for the lithium battery industry, electronic ceramics, high-end pharmaceuticals and high-grade pigments. Common ceramic components include ceramic inner cylinders, ceramic dispersion discs and ceramic mechanical seal rings, ensuring that the equipment does not introduce impurities during the grinding process.

The advantages of ceramic sand mills include efficient grinding, high-purity products, long service life, wide application and good economy. It can quickly reach nanometer-level fineness, ensure product stability, reduce the frequency of consumable replacement and downtime, covering various application scenarios from ordinary coatings to high-precision electronic materials. Although the single purchase cost may be higher, the long-term use cost is lower.

When choosing a

ceramic sand mill, it is necessary to clarify material characteristics, production capacity requirements and industry standards. Select vertical, horizontal or basket sand mills according to needs, and determine the material, ceramic bead specifications, cooling system and sealing method. Appropriate configuration can significantly improve grinding efficiency and product quality.

In conclusion, ceramic sand mills play an irreplaceable role in improving product quality, production efficiency and reducing costs through high-performance ceramic media and all-ceramic design.